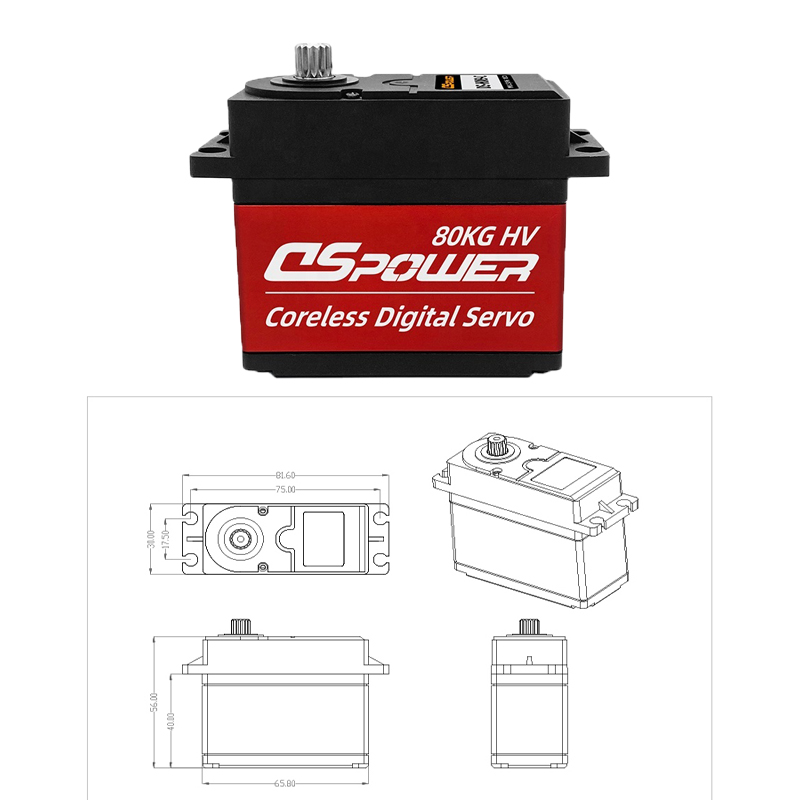

China New Product Sg90 Servo Specs - DS-H009-C Large HV High Torque Metal Gear 80KG Servo – Desheng

China New Product Sg90 Servo Specs - DS-H009-C Large HV High Torque Metal Gear 80KG Servo – Desheng Detail:

Application

|

Stall Torque |

≥70.0kgf.cm at 7.4V |

|

No Load Speed |

≤0.13sec./60°at 7.4V |

|

Operating Travel Angle |

90°±10°(1000~2000μs) |

|

Mechanical Limit Angle |

200° |

|

Weight |

200±1 g |

|

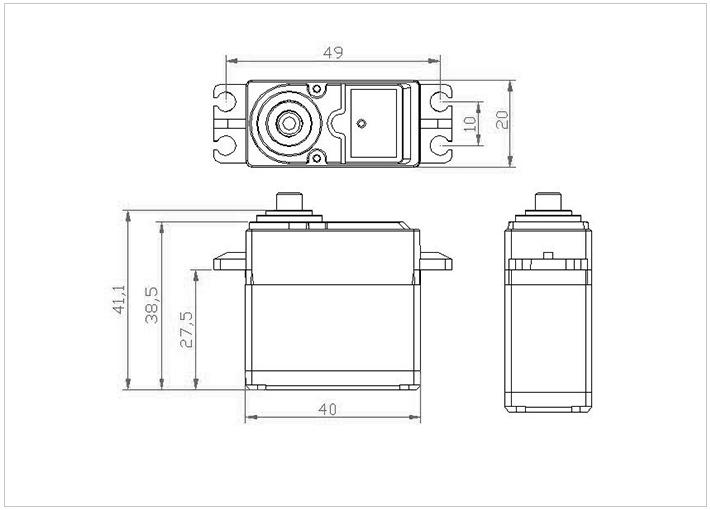

Size |

65.8 ×30 ×56 mm |

|

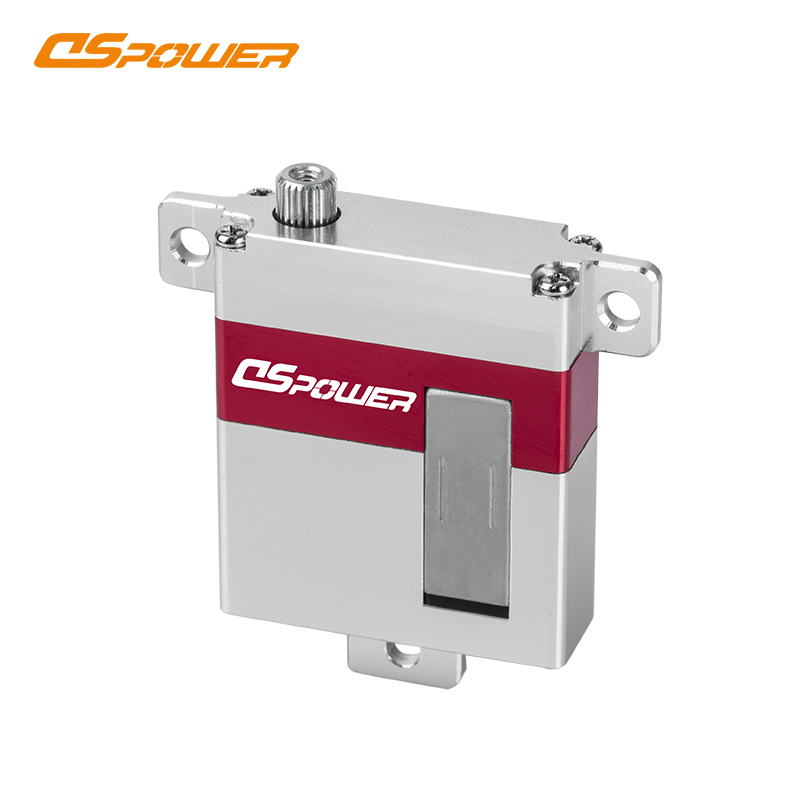

Case material |

Plastic top/bottom, Mid-Aluminiumalloy Casing |

|

Gear Set Material |

Durable Metal Gear |

|

Motor Type |

Coreless Motor |

Features

Application Scenarios

For with Remote Control Helicopters,Airplane, Robot, Boats,Robot Arm and Smart home. Support All Kind of R/C Toys and Arduino Experiments.

FAQ

Q. Can i ODM/ OEM and print my own logo on the products?

A: Yes, Through 10years research and development of servo, De Sheng technical team is professional and experienced to offer customized solution for OEM,ODM customer, which is one of our most competitive advantage.

If above online servos does not match your requirements, please do not hesitate to send message to us, we have hundreds of servos for optional, or customizing servos based on demands, it is our advantage!

Q. Servo Application?

A: DS-Power servo have wide application, Here are some of applications of our servos: RC model, education robot, desktop robot and service robot; Logistics system: shuttle car, sorting line, smart warehouse; Smart home: smart lock, switch controller; Safe-guard system: CCTV. Also agriculture, health care industry, military.

Q: For a customized servo, how long is the R&D time (Research& Development time)?

A: Normally, 10~50 business days, it depends on requirements, just some modification on standard servo or a totally new design item.

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for China New Product Sg90 Servo Specs - DS-H009-C Large HV High Torque Metal Gear 80KG Servo – Desheng , The product will supply to all over the world, such as: Myanmar, Cancun, Japan, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.