About DSpower

DSpower was founded in May, 2013. The main R & D production and sales of Drone servos, Robot servos, etc. We have more than 500+ employees, including more than 50+ R&D personnel, more than 30 quality inspection personnel, with more than 100+ patents; IS0:9001 and IS0:14001 certified enterprises. The maximum daily production capacity is more than 50,000 pieces.

Have You Ever Encountered These Problems with Your Drone?

Check Out Our Solutions!

UAV is always difficult to change direction and control during flight

When the UAV is flying at high altitude, it is always difficult to maintain balance, and the turning is very slow. It is unable to fly according to the predetermined route and take off and land stably.

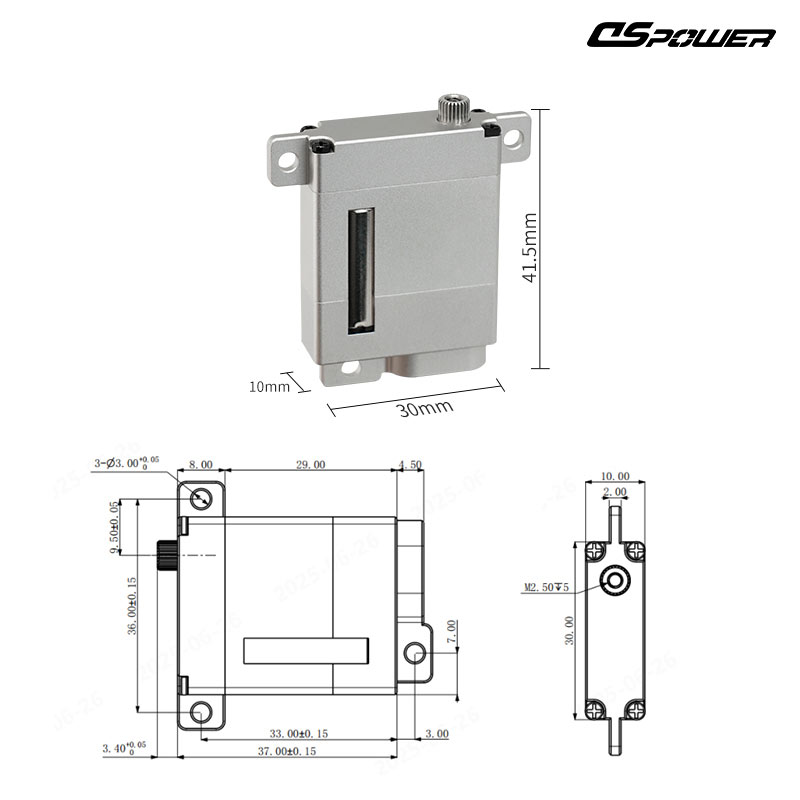

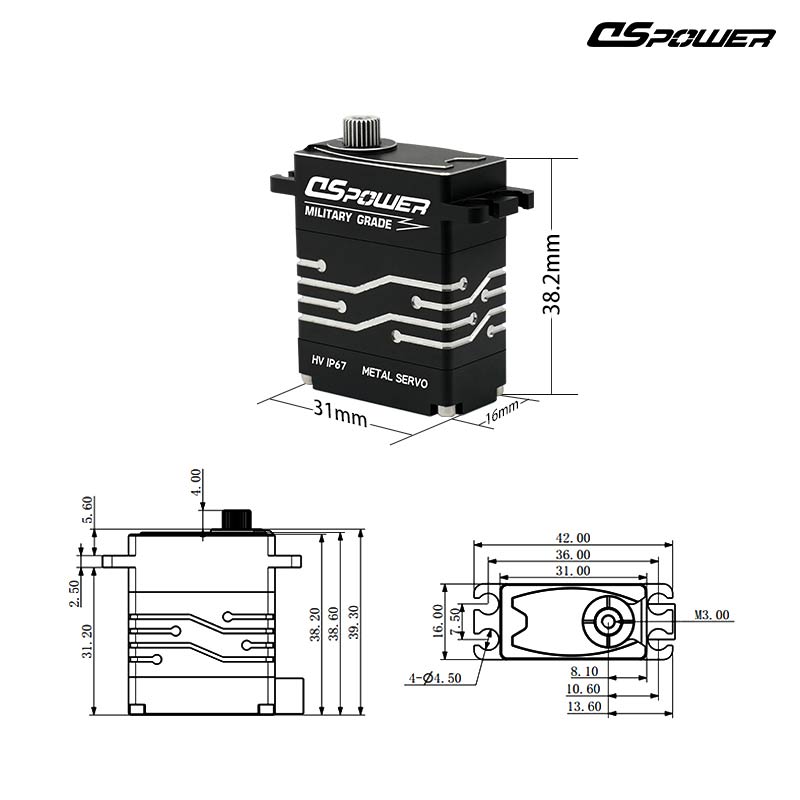

Product Model: DS-W009A

Operating Voltage: 9-12.6V DC

Standby Current: ≤30 mA

No Load Speed: ≤0.09sec/60°

Stall Current: ≤2.5A

Stall Torque: ≥8.0 kgf.cm

Rotating Direction: CCW

Operating Travel Angle: 120士10°

Mechanical Limit Angle: Unlimited

Angle deviation: ≤1°

Weight: 32士5g

Motor Type:Brushless Motor

Communication Interface: CAN BUS/PWM/RS485

Gear Set Material: Steel Gear

Case Material: Aluminum Alloy Case

Application Scenario: UAV Ailerons and Tail

Drone's camera gimbal and the cargo yard door do not open and close smoothly

When the drone is performing complex tasks, the camera gimbal may shake unsteadily, or the take off and landing gear may get stuck when opening and closing.

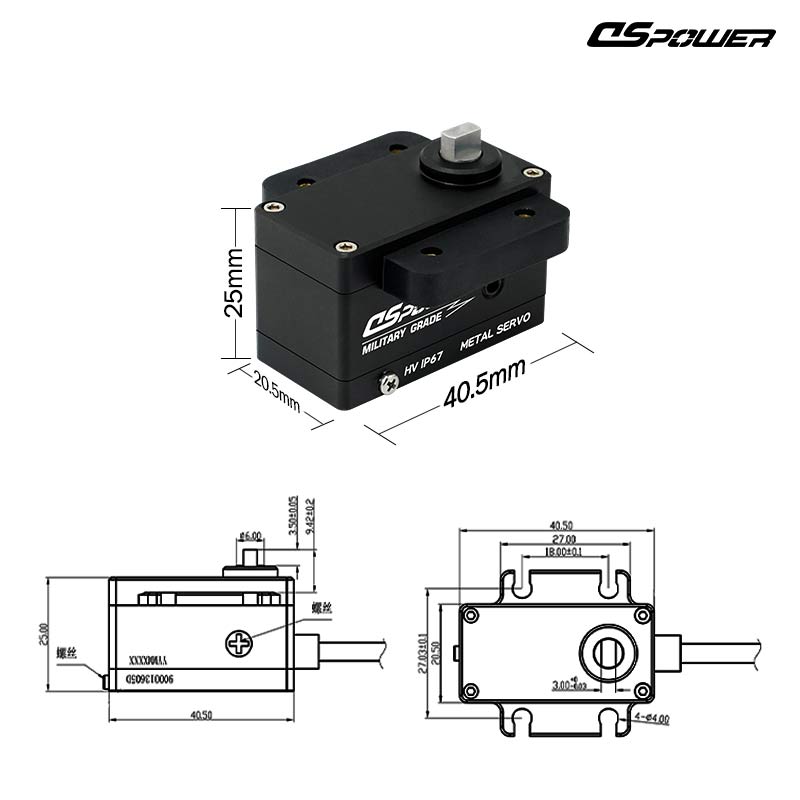

Product Model: DS-W006A

Operating Voltage: 9-12.6V DC

Standby Current: ≤30 mA

No Load Speed: ≤0.14sec/60°

Stall Current: ≤3.5A

Stall Torque: ≥22.0 kgf.cm

Rotating Direction: CW

Operating Travel Angle: 士100°

Mechanical Limit Angle: Unlimited

Angle deviation: ≤1°

Weight: 55士2.0g

Motor Type:Brushless Motor

Communication Interface: CAN BUS/PWM/RS485

Gear Set Material: Steel Gear

Case Material: Aluminum Alloy Case

Application Scenario: UAV Payload

The opening and closing control angles of the UAV's throttle and throttle are not accurate and the response speed is too slow

Every time the aircraft receives an electrical signal from the flight control system, the throttle and air damper opening and closing angles are always inaccurate and the feedback is too slow, resulting in reduced flight performance and fuel efficiency.

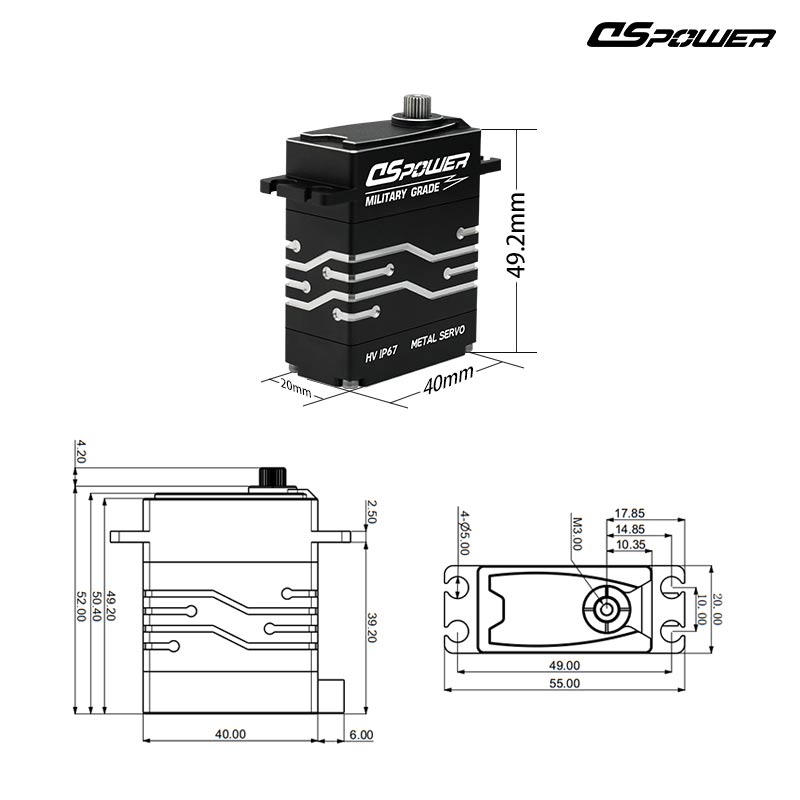

Product Model: DS-W004B

Operating Voltage: 9-16V DC

Standby Current: ≤40 mA

No load speed:≤0.1sec/60°

Stall Current: ≤3A

Stall Torque: ≥18.0 kgf.cm

Rotating Direction: CW

Operating Travel Angle: 360°

Mechanical Limit Angle: Unlimited

Angle deviation: ≤1°

Weight: 70.5士2.0g

Motor Type:Brushless Motor

Communication Interface: CAN BUS/PWM/RS485

Gear Set Material: Steel Gear

Case Material: Aluminum Alloy Case

Application Scenario: UAV Engine Throttle and Flap

The wiring method and control system are very complicated

Want to monitor current, position, temperature and other data in real time, but the communication method and wiring method are incompatible with the drone

Product Model: DS-W007A

Operating Voltage: 9-12V DC

Standby Current: ≤50 mA

No load speed:≤0.1sec/60°

Stall Current: ≤7A

Stall Torque: ≥60.0 kgf.cm

Rotating Direction: CW

Operating Travel Angle: ±100°

Mechanical Limit Angle: Unlimited

Angle deviation: ≤1°

Weight: 108士5.0g

Motor Type:Brushless Motor

Communication Interface: CAN BUS/PWM/RS485

Gear Set Material: Steel Gear

Case Material: Aluminum Alloy Case

Application Scenario: UAV Ailerons and Tail,UAV Payload and UAV Rudder Control

What Sets Our Factory Unique?

12+ Years Experience, Automated Production Workshop, Professional Customized Support

Unique Quality Inspection Equipment.

We have advanced CMM testing equipments, PJTH, Japan OSAKA Gear Mesh Tester,Servo integrated tester,Soundproof test chamber,pectral analyzing instruments and other routine testing equipments to ensure that the quality of our products meets high quality standards.

Automated Production Workshop

Our factory has more than 30 production lines,20,000 square meters of production workshop, with many intelligent equipments such as Japan HAMAI CNC type automatic hobbing machine, Japan Brother SPEEDIO high-speed drilling and tapping CNC machining center, Japan imported NISSEI PN40, NEX50 and other high-precision injection molding machines, automatic shaft pressing machine, and center shaft into the shell machine. The daily output is up to 50,000 pieces and the shipment is stable.

More Than 50+ R&D Team Support Customization

We have an experienced R&D team of more than 50 members to provide full technical support from prototype customization to mass production of drone servos for our customers worldwide. After more than 10 years of development, our team has been awarded more than 100+ patents.

International Certification & High Quality

Passed FCC, CE, ROHS, REACH, EMC product certification and more than 80+ patents.

Why DSpower Servos for your UAV?

Our wide product range covers most cases of possible applications. Beyond that, we modify existing standard actuators or develop completely new customized solutions – as fast, flexible and agile as the aerial vehicles they are made for!

DSpower standard servo product portfolio offers various sizes from 2g mini to heavy-duty brushless, with various functions such as data feedback, Resistant to harsh environments, various interfaces, etc.

DSpower Servos became the microservo supplier for the General Administration of Sport of China in 2025, thus meeting the market's future demand for certifiable servos!

Discuss your requirements with our experts and learn how DSpower develops your customized servos – or what kind of servos we can offer off-the-shelf.

With nearly 12 years of experience in air mobility, DSpower is best known as the leading manufacturer of electromechanical servos for aerial vehicles.

DSpower Servos impresses with its compact design combined with maximized actuating force, reliability and durability thanks to high-quality materials, technology and processing.

Our servos are tested for several thousand hours of use. We manufacture them in China under the strictest quality controls (ISO 9001:2015, EN 9100 under implementation) to ensure the high requirements for quality and functional safety.

Various electrical interfaces offer the possibility to monitor the operational status/health of the servo, for example by reading the current flow, internal temperature, current speed, etc.

What Stories Have Happened Between DSpower and Drone Servo?

“We have been collaborating with DJI, Ehang, and XAG, but we once had a big argument over the wear resistance and quietness of a small gear. After three days of discussion and simulation testing between our R&D teams, we finally achieved the desired effect, which led to the birth of DS-W008 and DS-W006. ”

Liu Huihua , CEO DSpower Servos

What Do Our Partners Say About Us?