Can a servo rotate continuously in a single direction? This question seems quite simple, but it is related to the key working principle of the servo. Conventional servos are equipped with a potentiometer to detect the rotation position and are used in conjunction with a control board to achieve angle positioning.

Therefore, ordinary servos can only move within a set angle range, such as 180 degrees or 270 degrees. However, there is a special 360 degree continuous rotation servo that removes the limit structure and can achieve continuous unidirectional rotation. However, this type of servo has lost the position feedback function and is more like a speed adjustable DC motor.

How does a servo achieve continuous 360 degree rotation?

A conventional servo, which receives feedback from an internal potentiometer, compares this signal with the control signal, drives the motor to the target angle, and then stops. A continuous rotation servo removes mechanical stops and modifies the control logic. The control signal does not correspond to a specific angle, but rather to rotation speed. For example, when the motor is stationary at neutral, the greater the deviation of the signal from neutral, the faster the rotation speed. This design retains the closed loop control characteristics of the servo, but sacrifices precise positioning capability.

In practical applications, this modified servo is highly adaptable to scenarios requiring uniform motion, such as enabling continuous movement of a robot chassis or maintaining a stable conveyor belt. However, it should be noted that due to the removal of the position sensor, it cannot precisely remain in a single position. This characteristic places it somewhere between a traditional servo and a standard DC motor, offering the advantage of speed control while losing the effectiveness of position servo.

Which types of servos can rotate infinitely?

On the market, there are three main types of servos capable of continuous rotation. First, there are 360-degree servos specifically designed for this purpose, which already support continuous rotation mode from the factory. Second, there are standard servos that are modified by removing the physical stoppers and adjusting the control circuitry. Third, there are bus servos that use serial communication and can be set to continuous rotation mode via command settings.

Of particular note are bus servos, which communicate via RS485 or CAN bus. They can be set to continuous rotation mode and can also read speed and load data in real time. These servos perform exceptionally well in applications such as robot joints and gimbals. Our DS-R026 brushless bus servo, for example, supports 360 degree continuous rotation and can adjust torque output on the fly.

Continuous Rotation Servo Control Method

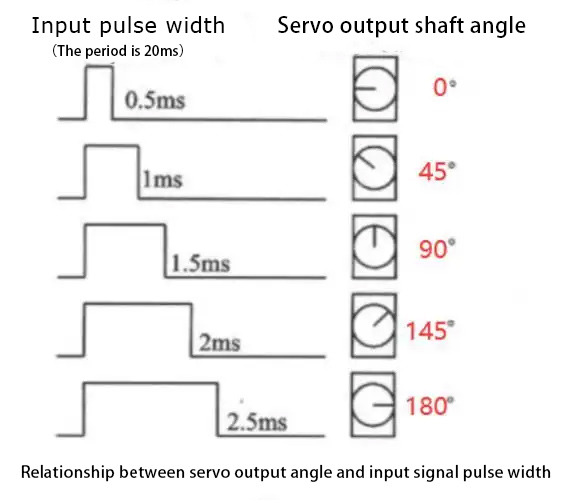

The control method of a continuous rotation servo differs from that of a traditional servo. The neutral position of the PWM signal represents a stopped state. Increasing the signal pulse width indicates forward rotation, while decreasing it indicates reverse rotation. The deviation of the pulse width from the neutral point determines the speed. This analog control method is simple and easy to use, but it is completely different from the angular control logic of a standard servo.

A digital bus servo offers greater control flexibility. A target speed can be set by sending a command. Acceleration and run time can also be set. The speed can be set up to 100 rpm. It will automatically stop after 10 seconds. This precise control makes continuous rotation servos more useful in automated equipment. For example, they can precisely control the travel distance of conveyor belts.

Application Limitations of Continuous Rotation Servos

While continuous rotation servos are practical, they have significant limitations, most notably their inability to achieve precise positioning, which restricts their use in applications requiring position control. Furthermore, because continuous operation generates significant heat, prolonged operation under high load may require additional cooling measures.

In actual projects, we often encounter customers attempting to use continuous rotation servos for position control. However, this isn\’t always practical. For example, one customer attempted to use a continuous rotation servo to control a robotic arm joint, only to find it impossible to stop accurately. They then switched to a multi turn absolute encoder servo to solve the problem. Therefore, choosing the right servo type is crucial.

How to choose the right servo type for your application?

When selecting a servo, the first thing to do is to clearly define your needs. If precise angle control is required, choose a standard servo. If continuous rotation is required and position is not a concern, choose a continuous rotation servo. If both continuous rotation and positional accuracy are required, a multi turn absolute encoder servo is the best choice.

For example, a continuous rotation servo is suitable for robot wheel driven motion. However, for robot joints, a servo that can accurately determine position is required. We often offer suggestions, allowing customers to choose based on their actual motion needs, rather than blindly pursuing a comprehensive range of features. Sometimes, combining different servo types can be a better solution.

DSpower’s Innovations in Servo Technology

We have conducted extensive research in servo technology, with a particular focus on brushless motors and intelligent control. Our newly developed brushless servo supports 360 degree continuous rotation and provides real time operational data feedback via bus communication. This makes it extremely reliable in complex applications such as intelligent robots and industrial automation equipment.

Recently, there was a project that used our high voltage brushless servo. Customer feedback showed that its performance remained stable after continuous operation for up to 8 hours. This was because the heat dissipation design was improved and the current control was very precise. The goal of technological innovation is to solve the pain points in actual applications, so that the servo can work reliably under various harsh conditions.

Post time: Oct-04-2025