In the world of valves, servos, as a relatively unpopular technology, are leading the industry’s transformation with their unique advantages and unlimited possibilities. Today, let us step into this magical field and explore how servos change the valve industry and the unlimited business opportunities it contains.

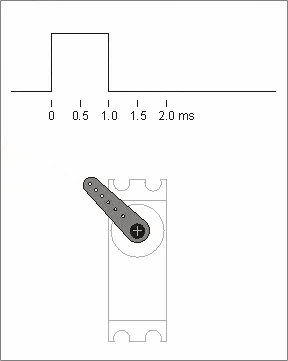

What is a servo?

Servo is a position servo driver, commonly used for the control of the rudder surface of model aircraft and drones. With the development of technology in recent years, the performance of servos has also risen, and has gradually been widely used in various high-end products such as robots, medical equipment, and industrial automation. The electric actuator of the electric valve is very similar to the servo, both of which are position and angle adjustments. Compared with the stepper motor, the servo has greater torque, higher precision, and can provide angle feedback and provide real-time position information.

Application fields of servo valves

Among many types of valves, electric valves have received extensive attention and applications due to their self-control ability, high torque, high precision and remote control. Among many electric valves, there are also many excellent types of valves that can be driven by servos, among which the most common ones are ball valves, butterfly valves and reversing valves.

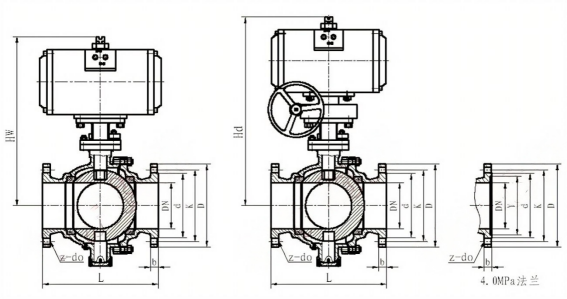

Application of servos in electric ball valves

Ball valves are widely used in the industrial field, and the key lies in their excellent durability and sealing performance.

Torque is an important indicator for measuring the performance of ball valves, and the servo has obvious advantages in this regard. The servo has a large torque and can maintain stable working performance in harsh environments. Not only that, the accuracy and response speed of the servo are better than those of the stepper motor, and it can provide real-time feedback on the angle, thereby achieving precise position control.

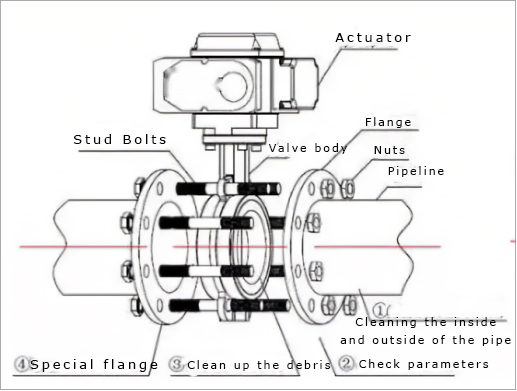

Application of servo in electric butterfly valve

Butterfly valves are also widely used in the industrial field due to their simple structure, easy operation, light weight and small size.

For butterfly valves, the high-precision control and fast response of the servo can significantly improve the flow control accuracy of the butterfly valve. At the same time, it can also realize autonomous work feedback, timely detect and correct angle deviations, and has the characteristics of strong integration and convenient installation.

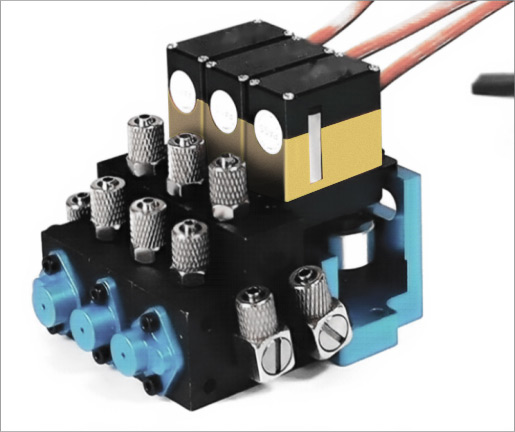

Application of servo in electric reversing valves

Directional valves are generally small in size and high in frequency. They are often used for communication, cutting and reversing of hydraulic oil flow and medical pipelines, as well as pressure unloading and sequential action control.

The servo is not only small in size, but also has excellent torque and precision among servers of the same size. It can also be controlled in series and set its own zero point.

In addition to these valves, servos can achieve good results in many fields. In industrial automation production lines, servos can achieve fast and precise control of valves to improve production efficiency; in the fields of petroleum, chemical industry, water treatment, etc., servos can accurately control the flow direction and flow of fluids to improve production safety and stability; and in medical equipment, servos can achieve precise control of medical equipment and improve the accuracy of medical diagnosis and treatment. In addition, servos also have broad application prospects in high-end fields such as aerospace, automobile manufacturing, and smart logistics.

Conclusion

The application of servo in the valve field has not only changed the valve driving mode, but also improved the valve control accuracy and working efficiency. In the fields of industrial automation, petrochemicals, medical equipment, etc., the emergence of servo valves has undoubtedly brought unprecedented breakthroughs to the industry. With its high precision, high torque, fast response and other characteristics, servo valves meet the needs of various complex working conditions and inject new vitality into the development of my country’s valve industry.

Post time: Jul-17-2025