DSPOWER began in 2013 and is a manufacturer focused on research and development, manufacturing and education for robot servos, intelligent robot servos, drone servos, and related accessories.

Since its establishment, we have focused on the requirements of robots and drone servos, and designed and developed servo products suitable for robot users.

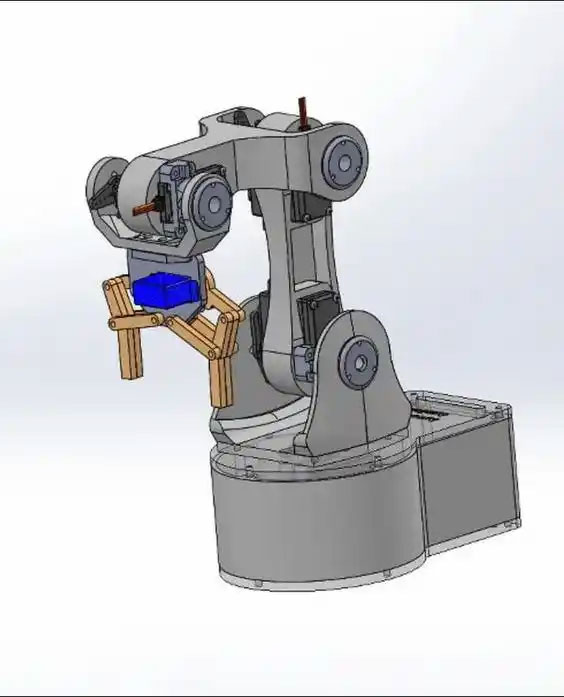

Today, we’ll share our robotic arm solutions.

The robotic arm performs motion control, just like injecting a soul into its steel skeleton, and the servo is the incredibly precise commander. In DSPOWER’s R&D workshop, every day we can see those components transformed from drawings into living mechanical dancers.

Today, I want to tell you how the servo makes the robotic arm operate as flexibly as a human arm, which involves both precise gears meshing with each other and intelligent scheduling.

How a Servo Controls the Angle of a Robotic Arm

The servo incorporates a highly intelligent feedback system. A potentiometer monitors the output shaft’s position in real time upon receiving a control signal. After comparing this position with the target position, it immediately adjusts the motor’s rotation.

This is similar to touching an object with your hand while shielding your eyes, where your fingers continuously make minute adjustments until precise positioning is achieved. The servo we’ve meticulously designed for cleaning robots utilizes TTL serial communication, enabling each joint to independently report position data. This ensures that when the robot arm remains at the pre-set angle, the error is less than 0.5 degrees.

In practical applications, each joint in a robotic arm must coordinate at different angles. For example, when grasping a tilted cup, the wrist servo must compensate for a 15 degree tilt, while the shoulder servo maintains 30 degrees of support.

This multi-angle coordination requires the servos to respond quickly. We employ a metal gear system that can maintain position stability even under 85 kgf.cm of torque, like adding fatigue-resistant muscles to the robotic arm.

Why is it necessary for multiple servos to work together?

A single servo can only achieve simple swings, yet a robotic arm must operate with the ultimate fluidity of a human hand. Imagine holding a pen and writing; this action requires the coordinated movement of the wrist, elbow, and shoulder.

In the five axis robotic vacuum cleaner developed by our partner, the front stage joint servos bear the load, the mid stage joint servos control the extension movement, and the end stage servos perform fine movements. This division of labor is like the symphony orchestral ensemble between the different instruments.

In a multi servo system, timing control is particularly critical. We once had a case where a robotic arm jittered while grasping an egg. We later discovered that this was due to a 10 millisecond delay in the response of the wrist and finger servos. By improving the PWM signal distribution, we were able to achieve perfect synchronization of all the servos, like a trained choir. Now, this system can smoothly grasp a raw egg without cracking it.

How does servo torque affect a robotic arm?

This is similar to the feeling of a human arm shaking.

However, higher torque isn’t always better. Excessive torque increases energy consumption and can also lead to bulky structures. The servos we designed for desktop robots can achieve most delicate operations with a torque of 6.3 kgf.cm. The key is to match the torque to the load requirements of the robotic arm, just as when choosing a car engine, you don’t always need to pursue maximum horsepower.

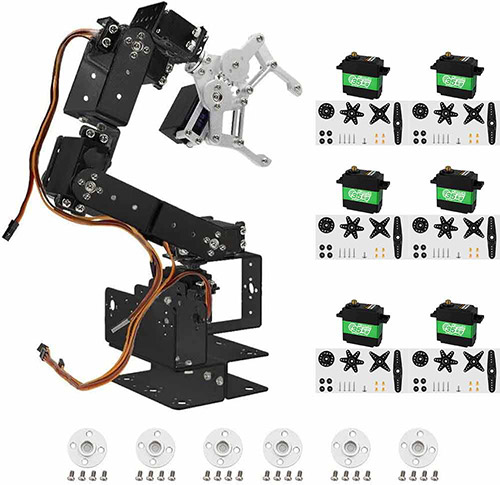

How to Choose a Robotic Arm Servo Model

When selecting a servo model, consider the robot’s operating scenario. For applications that require frequent starts and stops, a digital servo with a brake function is recommended. One customer case we encountered involved an automated production line that required the robot arm to achieve 20 precise stops per minute. Conventional analog servos would suffer from cumulative errors, while digital servos, with their higher refresh rate, perfectly address this problem.

Matching dimensions is also crucial. In the past, some customers placed standard servos in compact robotic arms, resulting in poor heat dissipation. We subsequently developed a specially designed 26mm gripper servo, which is 40% smaller while maintaining a torque of 3 kg·cm. It’s like tailoring clothing for a robotic arm—it needs to allow for free movement without being too loose.

What are the differences in servo control protocols?

The PWM protocol, similar to a beat-beat conductor, transmits commands via pulse width, while the TTL serial protocol, like a conversation, can transmit more complex parameters. In the DSPOWER lab, we often compare these two protocols.

PWM is suitable for simple point to point control, like turning a light on or off, while TTL can simultaneously obtain multiple feedback signals, such as position, temperature, and current.

Currently, more and more robotic arms are adopting hybrid protocols, such as our bionic robotic arm project. Basic movements utilize PWM control to ensure real-time performance, while fine tuning with TTL transmits detailed parameters.

This is like driving a car, where you need to use the pedals to control speed and the dashboard to monitor status. This flexible configuration allows robotic arms to adapt to increasingly complex working environments.

How to Improve Servo Control Accuracy

Improving accuracy requires both hardware and software. In hardware, we use 0.1mm precision machined gears to reduce transmission backlash. A customer reported a persistent 2mm wobble at the end of the robotic arm. After investigation, we found that this was caused by gear meshing backlash.

By replacing the gears with a helical gear structure, the issue was resolved. This is similar to a watch movement: the accuracy of each gear affects the overall timekeeping.

Equally crucial is the software. Our anti-shake system predicts the inertia of the robotic arm’s motion and compensates for it in advance. For example, during an emergency stop, it generates a reverse fine-tuning signal to eliminate overshoot caused by inertia, much like an experienced driver gently applies the brake pedal to ensure a smooth, unobstructed stop.

Post time: Oct-23-2025