To gain a deeper understanding of why servos are prone to failure, you need to delve into several aspects, including their structure, materials, operating principles, servo selection, operating environment, and servo failure points. Then, you need to examine the operating environment and the factors that led to the failure.

1、Structure, material and working principle of servo:

What is a servo? A servo is a position servo actuator suitable for closed loop control applications requiring continuous and maintained angle changes.

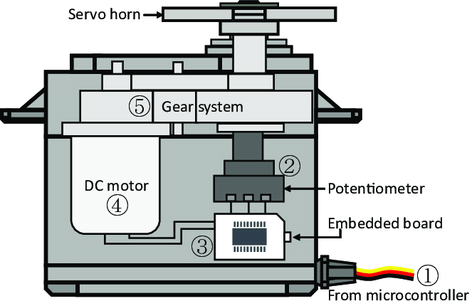

The structure and operating principle of a servo: It primarily consists of a housing, circuit board, drive motor, reducer, and position detection element. The operating principle is that a controller sends pulses/commands to the servo, which, through the IC on the circuit board, drives the motor to rotate.

The reduction gear transmits power to the servo’s output gear, driving the swing arm or transmission mechanism. Simultaneously, a position detector collects position information to determine whether the position has been reached.

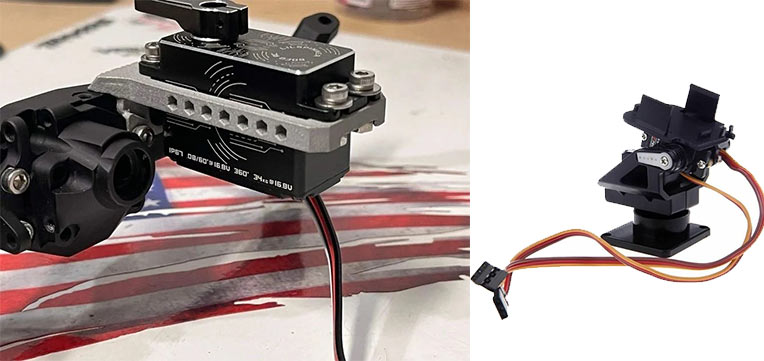

The above picture shows the internal structure of 99% of the servos on the market. Most of the external structures are as follows:

The reason why I show the structure of the servo is that you can see in the picture that the power output of the servo is only provided by the output diagram that extends less than 10mm. So it is very limited.

Most single axis and dual axis mounting configurations are shown in the diagram above. This configuration is highly susceptible to stalling. In the second diagram, the single axis servo responsible for rotating the gripper in the robotic arm, in addition to its own rotational force, also bears the weight of the gripper and the object it clamps.

This can easily cause the output shaft to deform, shifting or deforming the internal gears, and indirectly causing the entire gearbox to jam. Therefore, the servo output connector can only withstand forces in the rotational direction and cannot be subjected to external forces in other directions.

2、Selection of servo:

We know that servo gears are easily affected by external forces in other directions, leading to internal damage to the gearbox. In addition to optimizing the external structure so that the servo is only subjected to torque output in the direction of rotation, we can change the gearbox material. If the servo gears are plastic, replace them with metal ones.

Metal gears are divided into aluminum, iron, copper, steel, and titanium. Choose the appropriate gear material based on the load, life expectancy, stability requirements, and cost budget. You can also combine gears of various materials to meet different requirements. For example, where the torque is low in areas where the motor is rotating at high speeds, relatively low strength and low cost gears can be used.

Where the speed is lower and the load is greater near the output head, including the output head, stronger gears can be used. Different materials will also affect the sound. For example, the harder the steel teeth, the sharper the sound. This can be improved by adding grease.

3、Usage environment:

After requesting product specifications from the factory, we often only focus on a few parameters: stall torque and voltage, and that’s it. My advice is to find a store with a company logo, verify it’s the manufacturer’s store, and then place your order.

Servos are now used in a wide range of applications beyond model aircraft. Depending on the specific environment, more parameters need to be analyzed. For example, low temperature, sustained load capacity, rated current, angle feedback, center position calibration, temperature detection, continuous rotation operating modes, noise level, lifespan, and so on.

Most sellers don’t provide these parameters, as they are often agents who assume servos are only used on model aircraft.

4、Servo failure point:

It’s recommended to pay close attention to the operating temperature, rated load, rated current, housing and gear material type, structure, motor type, any protective measures, electronic control functions, and the manufacturer’s reliability test data, as noted in the data sheet.

These parameters can help assess whether the servo meets the requirements of the current environment or your project.

Summary:

Servos are consumable items and can easily be damaged if used in environments that do not meet their specifications. Before selecting a servo, it’s important to consider several models and find a reliable servo manufacturer that meets your project’s needs and can support customization.

Communicating with experienced sales representatives in detail about project requirements and planning is crucial for ensuring the manufacturer’s full cooperation. Ultimately, a company’s success depends on deep, profitable collaboration between both parties. For example, at DSPOWER, we have 12 years of experience in servo manufacturing. Buyers are welcome to contact us!

Post time: Oct-16-2025