DSPOWER began in 2012, is a focus on research and development manufacturing education robot servo, intelligent robot servo and Building Block servo

When designing robots or smart devices, the angular accuracy of servo motors is often an easily overlooked yet crucial parameter. You may have encountered situations where the servo motor fails to rotate to its intended position, or the position reached varies slightly each time, causing instability in the entire system.

This is generally because you haven’t paid attention to the standard angular accuracy value of the servo motor, and have only checked basic parameters such as torque and speed.

What is Servo Motor Angular Accuracy?

Servo motor angular accuracy refers to the degree of deviation between the actual rotation position and the theoretical target position after receiving a control signal. For example, a servo motor with ±1° accuracy, theoretically rotating to 90°, might actually be positioned between 89° and 91°. This standard accuracy value is usually given by the servo motor manufacturer in the technical specifications.

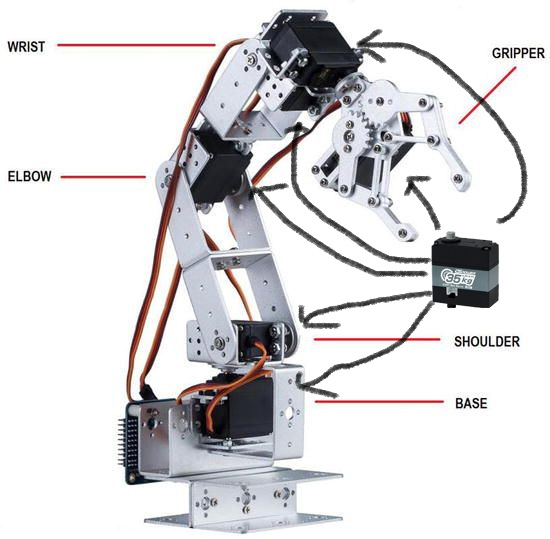

It is one of the core indicators for measuring servo motor performance. High precision servos ensure accurate and repeatable movements of your equipment, especially in scenarios requiring precise control, such as robotic arm grasping and camera gimbal positioning.

Understanding the importance of angular accuracy, which is not always readily available, helps you avoid many potential problems at the crucial initial stage of a project. Inexpensive but low-accuracy servos can actually cause cumulative errors in the entire system, ultimately affecting its overall functionality and leading to adverse effects.

Therefore, when selecting a servo, you must carefully review the accuracy-related parameters in the specifications and prioritize products that clearly state their accuracy standards, rather than making decisions based solely on past experience or price.

Why Angular Accuracy is Crucial for Projects

Angular accuracy directly determines the reliable execution of tasks by equipment. For example, if you are working on an automated tracking system, poor servo accuracy will prevent the camera from accurately targeting the target, significantly reducing tracking effectiveness. Similarly, in industrial automation, low servo can cause robotic arm malfunctions and even production problems.

Insufficient precision not only impacts performance but also significantly increases setup time and costs due to the need for repeated calibrations or component replacements.

From a user experience perspective, high precision servos enable smoother and more professional device operation. For example, in educational robots or smart toys, precise movements enhance interactivity and prevent user frustration caused by unresponsive devices.

Therefore, while investing in high-precision servos may seem to increase initial costs, it actually improves project success rates and long-term stability, making it a highly cost-effective choice.

How to Choose High Precision Servos

When selecting a high precision servo, the first step is to check the product specifications and look for clear numerical values for angular accuracy, such as ±0.5° or ±1°. Generally speaking, digital servos are more accurate than analog servos because they use microprocessors for closed-loop control, allowing for real-time position adjustments.

At the same time, pay attention to the type of servo; brushless motors or coreless motors often have advantages in terms of accuracy and lifespan, while coreless motors offer advantages in longer continuous operating time and better heat dissipation.

Consider the application scenario. If your project requires fast response and high precision, you can choose a digital servo that supports a high refresh rate; if your budget is limited but accuracy requirements are not high, a standard servo may suffice.

Additionally, read user reviews and test reports to understand the accuracy performance in actual use, avoiding decisions based solely on theoretical parameters. Remember, high-precision servos generally require higher voltage and better control protocol support, such as TTL serial buses or CAN buses.

What Factors Affect Servo Accuracy?

The accuracy of a servo motor is affected by a variety of factors, encompassing both internal structure and external environment. Internal factors primarily include gear backlash, motor type, and feedback system. Servos with large gear backlash will experience hysteresis during reverse rotation, leading to decreased accuracy.

However, closed-loop servos with encoders utilize feedback mechanisms to reduce errors, thereby improving accuracy. External factors include power supply voltage stability, control signal quality, and load variations.

For example, voltage fluctuations can easily cause uneven servo rotation speeds, affecting positional accuracy. Noise in the control signal can also interfere with the servo’s command interpretation. Furthermore, excessive load or improper installation can also lead to accuracy loss.

Therefore, when using high precision servos, it is essential to ensure a stable power supply, a clean signal, and a well-designed mechanical structure to maximize performance.

How to Test and Calibrate Servo Accuracy?

You can use simple tools, such as an angle gauge or laser pointer, to send precise signals to the controller to test the servo’s accuracy. Rotate the servo at multiple target angles, such as 0°, 90°, and 180°, then measure the actual position and calculate the deviation.

Repeat this process multiple times and take the average to evaluate repeatability. If the deviation is large, calibration may be necessary. Many digital servos support software calibration, which compensates for errors by adjusting control parameters.

Calibration typically involves sending calibration commands or using specialized software. For example, a microcontroller might send a PWM signal and record the difference between the actual position and the theoretical value, then add an offset to the code to correct for it.

Regular testing and calibration can extend the servo’s lifespan and ensure long-term stable operation. For critical applications, it is recommended to complete these steps before installation to avoid problems during later debugging.

Common Applications of High Precision Servos

High precision servos are widely used in fields requiring precise control, such as robotics, aerospace, and medical equipment. In robotics, it’s used in joint actuators to ensure smooth movements and accurate grasping.

In drone gimbals, high precision servos help stabilize cameras, resulting in clear images. Furthermore, automatic curtains and security cameras in smart homes rely on servo precision for smooth operation.

In these scenarios, precision is directly related to system safety and efficiency. For example, in medical robots, even minute errors can lead to surgical failure, so it’s crucial to choose high precision, high reliability servos. Understanding these applications can help you better plan your projects and select appropriate servo types to improve overall performance.

Post time: Nov-08-2025