DS-R003C 35kg Stainless Steel Gear High Torque Pwm Servo

DSpower R003C 35kg Plastic Casing Metal Gear PWM Digital Servo is an advanced servo motor engineered for applications demanding high torque, durability, and precise control. With its combination of a robust plastic casing, metal gears, and digital PWM control, this servo is tailored for projects where strength, resilience, and digital precision are essential.

Key Features and Functions:

High Torque Output (35kg): This servo is designed to deliver a substantial torque output of 35 kilograms, making it ideal for applications requiring significant force and precise control.

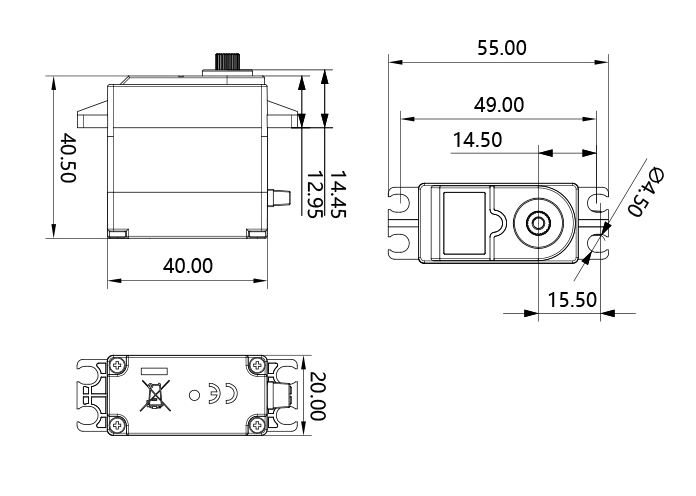

Plastic Casing: Equipped with a sturdy plastic casing, the servo strikes a balance between weight efficiency and structural integrity. The plastic construction contributes to a lightweight profile without compromising durability.

Metal Gear Design: The servo features metal gears, ensuring strength, durability, and efficient power transmission. Metal gears are essential for applications demanding resilience and the ability to handle heavy loads.

PWM Digital Control: Utilizing Pulse-Width Modulation (PWM) technology, the servo allows for digital control with precise signal modulation. This digital control ensures accurate and repeatable movements, making it suitable for applications where precision is crucial.

High Resolution: The digital nature of the servo allows for high-resolution control, enabling fine-tuned and smooth movements. This is particularly valuable in applications that demand precise positioning.

Wide Operating Voltage Range: The servo is designed to operate within a versatile voltage range, providing flexibility for different power supply systems.

Plug-and-Play Integration: Engineered for seamless integration, the servo is often compatible with standard PWM control systems. This enables easy control via microcontrollers, remote controls, or other digital control devices.

Application Scenarios

Robotics: Ideal for high-torque applications in robotics, the servo can be used in various robotic components, including arms, grippers, and other mechanisms requiring powerful and precise control.

RC Vehicles: Well-suited for remote-controlled vehicles, such as cars, trucks, boats, and airplanes, where the combination of high torque, durable metal gears, and digital precision is crucial for optimum performance.

Aerospace Models: In model aircraft and aerospace projects, the servo's high torque output and durable metal gears contribute to precise control of control surfaces and other critical components.

Industrial Automation: The servo can be integrated into various industrial automation systems, including conveyor controls, robotic assembly lines, and other applications requiring robust and precise movement.

Research and Development: In research and development settings, the servo is valuable for prototyping and testing, particularly in projects that demand high torque and digital precision.

Automation in Compact Spaces: Suitable for applications where maintaining a low profile is crucial, such as compact robotics, small-scale automation, and experimental setups.

DSpower R003C PWM Digital Servo combines high torque with digital precision, making it suitable for a diverse range of applications in robotics, RC vehicles, aerospace models, industrial automation, and research and development.

FAQ

A: Our servo have FCC, CE, ROHS certification.

A: Normally, 10~50 business days, it depends on requirements, just some modification on standard servo or a totally new design item.

A: Yes, Through 10years research and development of servo, De Sheng technical team is professional and experienced to offer customized solution for OEM,ODM customer, which is one of our most competitive advantage.

If above online servos does not match your requirements, please do not hesitate to send message to us, we have hundreds of servos for optional, or customizing servos based on demands, it is our advantage!

A: DS-Power servo have wide application, Here are some of applications of our servos: RC model, education robot, desktop robot and service robot; Logistics system: shuttle car, sorting line, smart warehouse; Smart home: smart lock, switch controller; Safe-guard system: CCTV. Also agriculture, health care industry, military.