The Application of Micro Servo in Smart Sweeper Robots

Our micro servos can be customized with different parameters to meet customers' needs, and used for the drive wheel lifting module of the sweeper robot, the mop control module, the sweeper radar module and so on.

Drive Wheel Lifting Module (On Demand)

We can customize the Micro Servo to support various lifting methods of the Drive Wheel Lifting Module, such as pull-wire type, robotic arm type and cam jacking type. Help sweeper robot overcome obstacles and fit different heights.

Product Model: DS-S009A

Operating Voltage: 6.0~7.4V DC

Standby Current: ≤12 mA

No Load Current: ≤160 mA at 7.4

Stall Current: ≤2.6A at7.4

Stall Torque: ≥6.0 kgf.cm at 7.4

Rotating Direction: CCW

Pulse Width Range: 1000-2000μs

Operating Travel Angle: 180士10°

Mechanical Limit Angle: 360°

Angle deviation: ≤1°

Weight: 21.2 士 0.5g

Communication Interface: PWM

Gear Set Material: Metal Gear

Case Material: Metal Casing

Protective Mechanism: Overload protection/overcurrent protection/overvoltage protection

Mop Control Module (On Demand)

We can customize the Micro Servos to meet the customer's needs, through the servo control mop lifting module, to achieve the control of different height positions, and meet the needs of carpet avoidance, floor deep cleaning, mop self-cleaning etc.

Product Model: DS-S006M

Operating Voltage: 4.8-6V DC

Standby Current: ≤8mA at6.0V

No Load Current: ≤150mA at 4.8V; ≤170mA at 6.0V

Stall Current: ≤700mA at 4.8V; ≤800mA at 6.0V

Stall Torque: ≥1.3kgf.cm at 4.8V; ≥1.5kgf*cm at6.0V

Rotating Direction: CCW

Pulse Width Range: 500~2500μs

Operating Travel Angle: 90°士10°

Mechanical Limit Angle: 210°

Angle deviation: ≤1°

Weight: 13.5± 0.5g

Communication Interface: PWM

Gear Set Material: Metal gear

Case Material: ABS

Protective Mechanism: Overload protection/overcurrent protection/overvoltage protection

Sweeper Radar Module (On Demand)

We can customize Micro Servos based on customer needs, The mini servo controls the lifting of the radar module, to realize a wider range of radar detection, improve the robot vacuum's ability to cross the obstacles, and increase the passability.

Product Model: DS-S006

Operating Voltage: 4.8~6V DC

Standby Current: ≤8mA at 6.0V

No Load Current: ≤150mA at 4.8V; ≤170mA at6.0V

Stall Current: ≤700mA at 4.8V; ≤800mA at6.0V

Stall Torque: ≥1.3kgf.cm at 4.8V; ≥1.5kgf.cm at6.0V

Rotating Direction: CCW

Pulse Width Range: 500~2500 μs

Operating Travel Angle: 90°土10°

Mechanical Limit Angle: 210°

Angle deviation: ≤1°

Weight: 9士 0.5g

Communication Interface: PWM

Gear Set Material: Plastic gear

Case Material: ABS

Protective Mechanism: Overload protection/overcurrent protection/overvoltage protection

More Uses for Micro Servo

We can customize the Micro Servo to meet the customer's needs, through the servo control tank valve module, the valve lifting system control, to achieve automatic control of the valve opening and closing function.

Each product is different request, We can offer customized,please Contact Us.

We can customize the servo according to the customer's needs, and control the robotic arm scraper module through the servo to achieve right-angle cleaning, completely fit the ground, and improve the cleaning efficiency.

Each product is different request, We can offer customized,please Contact Us.

We can customize the servo according to the customer's requirements, through the servo control lens wiper, steering system module, clear underwater operating environment, free walking, improve cleaning efficiency.

Each product is different request, We can offer customized,please Contact Us.

We can customize the servo according to the customer's requirements, and control the cleaning system and steering system module through the servo, which can walk freely without obstacles, clean the knives intelligently, and improve the efficiency of lawn mowing.

Each product is different request, We can offer customized,please Contact Us.

We can customize servo motors based on customer needs. The servo motors control the lifting modules, mounting system modules, and power gate valve modules to perform various complex drone operations, such as lifting off, dropping objects, speeding up flight, and saving energy.

Each product is different request, We can offer customized,please Contact Us.

We have 10+ experience in servo customization, we can customize servos to meet clients' needs and deeply participate in clients' product development process, applying servos to drones, pool cleaning machines, snow removal robots, lawn mowing robots and other products.

Due to space constraints, we cannot show all of our 10 years of servo application scenarios in various industries, for more industry examples, contact us now!

Contact us to customize your product application scenario together!

Found a Servo Solution for Your Robot?

We have a R&D team of more than 40+ people to support your project!

Highlights of Our Servos

Self-developed protection system of mechanical transmission and electric drive to utilize the best function of the servo.

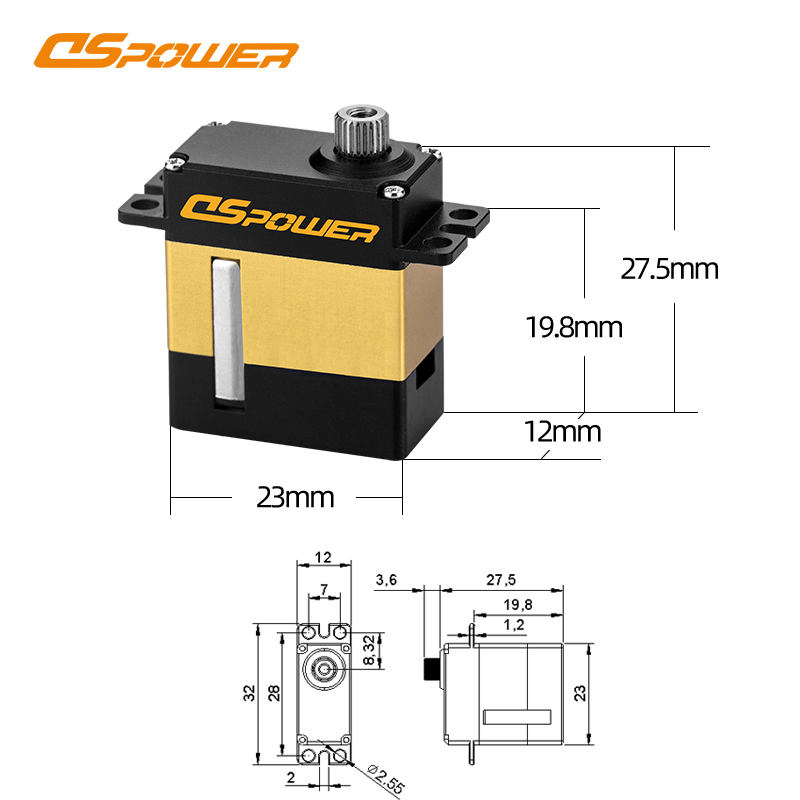

Featured Micro Servos Products

Product Model: DS-S009A

Operating Voltage: 6.0~7.4V DC

Standby Current: ≤12 mA

No Load Current: ≤160 mA at 7.4

Stall Current: ≤2.6A at7.4

Stall Torque: ≥6.0 kgf.cm at 7.4

Rotating Direction: CCW

Pulse Width Range: 1000-2000μs

Operating Travel Angle: 180士10°

Mechanical Limit Angle: 360°

Angle deviation: ≤1°

Weight: 21.2 士 0.5g

Communication Interface: PWM

Gear Set Material: Metal Gear

Case Material: Metal Casing

Protective Mechanism: Overload protection/overcurrent protection/overvoltage protection

Product Model: DS-S006M

Operating Voltage: 4.8-6V DC

Standby Current: ≤8mA at6.0V

No Load Current: ≤150mA at 4.8V; ≤170mA at 6.0V

Stall Current: ≤700mA at 4.8V; ≤800mA at 6.0V

Stall Torque: ≥1.3kgf.cm at 4.8V; ≥1.5kgf*cm at6.0V

Rotating Direction: CCW

Pulse Width Range: 500~2500μs

Operating Travel Angle: 90°士10°

Mechanical Limit Angle: 210°

Angle deviation: ≤1°

Weight: 13.5± 0.5g

Communication Interface: PWM

Gear Set Material: Metal gear

Case Material: ABS

Protective Mechanism: Overload protection/overcurrent protection/overvoltage protection

Product Model: DS-S006

Operating Voltage: 4.8~6V DC

Standby Current: ≤8mA at 6.0V

No Load Current: ≤150mA at 4.8V; ≤170mA at6.0V

Stall Current: ≤700mA at 4.8V; ≤800mA at6.0V

Stall Torque: ≥1.3kgf.cm at 4.8V; ≥1.5kgf.cm at6.0V

Rotating Direction: CCW

Pulse Width Range: 500~2500 μs

Operating Travel Angle: 90°土10°

Mechanical Limit Angle: 210°

Angle deviation: ≤1°

Weight: 9士 0.5g

Communication Interface: PWM

Gear Set Material: Plastic gear

Case Material: ABS

Protective Mechanism: Overload protection/overcurrent protection/overvoltage protection

No Product for Your Needs?

Please supply your specific function requirements and tech specs. Our product engineers will recommend the apposite model for your needs.

Our ODM Service Process

FAQs

A: Yes, Through 10years research and development of servo, De Sheng technical team is professional and experienced to offer customized solution for OEM,ODM customer, which is one of our most competitive advantage.

If above online servos does not match your requirements, please do not hesitate to send message to us, we have hundreds of servos for optional, or customizing servos based on demands, it is our advantage!

A: Sample order is acceptable for testing your market and checking our quality And we have strict quality control systems from raw material incoming until finished product delivery out.

Normally, 10~50 business days, it depends on requirements, just some modification on standard servo or a totally new design item.

A: - Order less than 5000pcs, it will take 3-15 business days.

What Sets Our Factory Unique?

10+ years experience, self-developed protection system, automated production, professional customized support

More Than 40+ R&D Team Support Customization

We have an experienced R&D team of more than 40 members to provide full technical support from prototype customization to mass production of micro servos for our customers worldwide. After more than 10 years of development, our team has been awarded more than 100+ patents.

Automated Production

Our factory has more than 30 production lines, with many intelligent equipments such as Japan HAMAI CNC type automatic hobbing machine, Japan Brother SPEEDIO high-speed drilling and tapping CNC machining center, Japan imported NISSEI PN40, NEX50 and other high-precision injection molding machines, automatic shaft pressing machine, and center shaft into the shell machine. The daily output is up to 50,000 pieces and the shipment is stable.

About DSpower

DSpower was founded in May, 2013. The main R & D production and sales of servos, micro-servos, etc.; products are widely used in model toys, drones, STEAM education, robotics, smart home, intelligent logistics and industrial automation and other fields. We have more than 500+ employees, including more than 40+ R&D personnel, more than 30 quality inspection personnel, with more than 100+ patents; IS0:9001 and IS0:14001 certified enterprises. The maximum daily production capacity is more than 50,000 pieces.

Get a Servo Solution to Help You Succeed!

We have a R&D team of more than 40+ people to support your project!